HyREXⓇ

Hydrogen reduction

ironmaking technology

to reduce carbon emissions

ironmaking technology

to reduce carbon emissions

HOME Hyrex

Ironmaking Technology

by Hydrogen Reduction

and Electrical Smelting

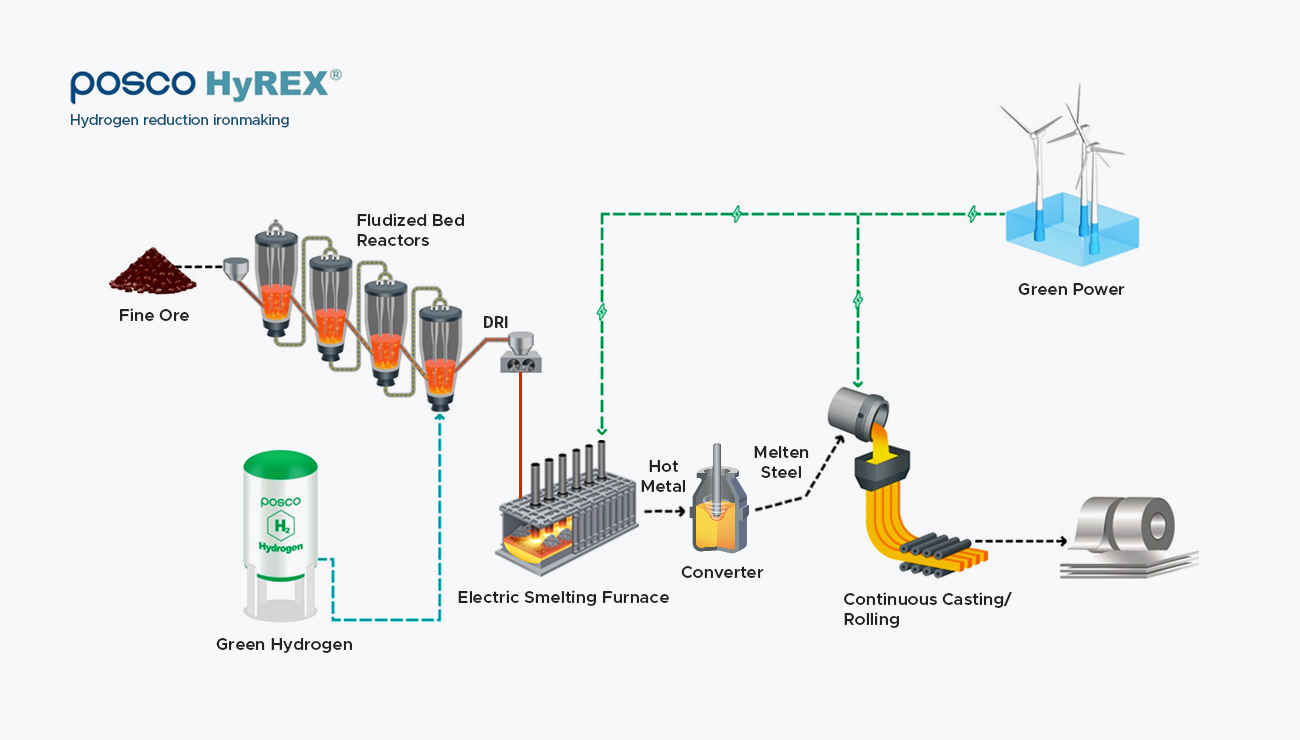

The conventional method for producing iron involves using heat and gas generated from coal. However, HyREX uses hydrogen to convert fine iron ore into Direct Reduced Iron (DRI). Then, they are charged into an Electric Smelting Furnace (ESF) to produce hot metal.

From FINEXⓇ

to HyREXⓇ

to HyREXⓇ

The proven success of FINEX allows POSCO to embark on a new journey.

HyREX,

Innovation Builds on More Innovation

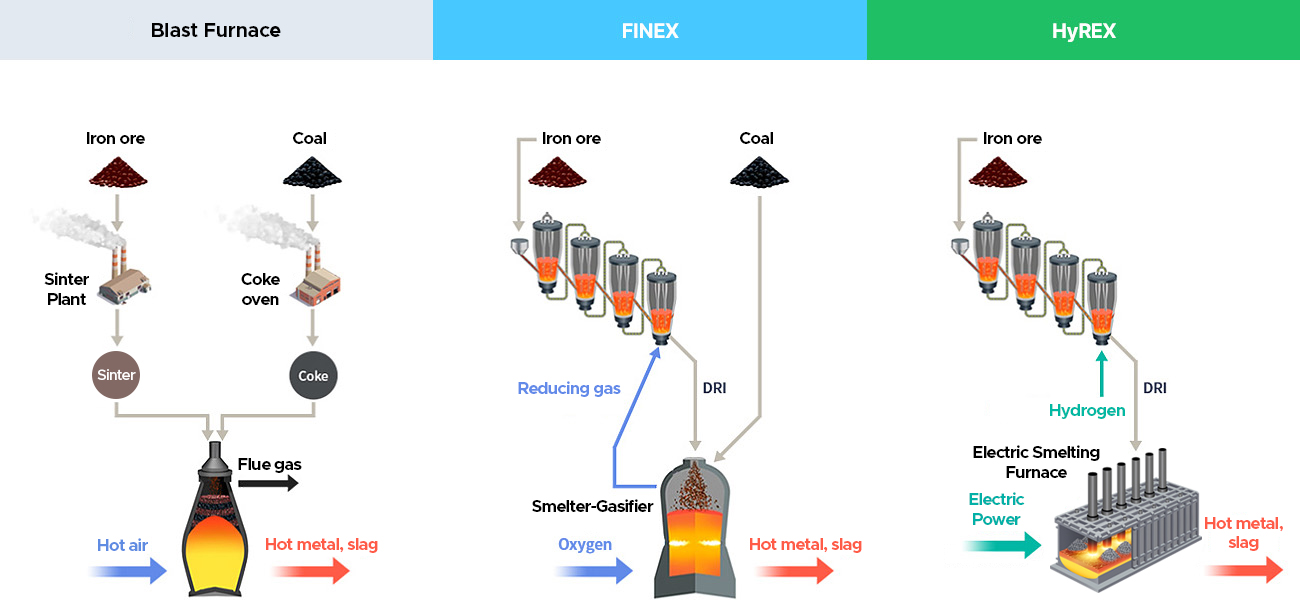

The conventional integrated steelworks operates on the blast furnace, which relies on sintered ore and coke agglomerated from fine iron ore and coal. However, POSCO has developed a breakthrough technology, FINEX, that can produce hot metal using fine iron ore and coal; hence, sintering and coking processes can be eliminated. Currently, POSCO has two FINEX plants in operation, with output capacities of 1.5Mtpa and 2.0Mtpa. Building on the success of FINEX, HyREX will adopt the proven fluidized bed reactor technology and use hydrogen, instead of coal, as the reducing agent.

What Sets HyREX Apart?

-

01Reduction by Fluidized Bed ReactorsIn a fluidized bed furnace, the hot reducing gas is uniformly introduced through a distribution plate designed with multiple openings. The reducing gas causes solids to float like a fluid, hence fluidizes, to evenly combine the fine ore particles, generating efficient reduction performance. This unique characteristic of the fluidized bed technology is what allows us to use fine iron ore without having to put it through additional agglomeration process.

-

02Raw MaterialsUnlike conventional DR shafts that use lumpy pellets, the HyREX fluidized bed is able to take fine iron ore, as is. As a result, HyREX bypasses the pelletizing process, helping to lower production cost and CO2 emissions. Furthermore, the electric smelting furnace of the HyREX process is able to take H2 DRI made from low-grade iron ore. This adds another enhancement to the economic efficiency of steelmaking.

-

03Temperature Control TechnologyAs hydrogen reduction is essentially endothermic; hence, the generated heat is insufficient to sustain the intended reaction. Therefore, additional heat must be supplied from an external source. For this reason, HyREX fluidized bed reactors are constructed in multiple sequence, allowing for effective temperature control of each reactor.

Here is a short video clip to summarize what we have learned